-

Shop By CategoryProducts

- Specials

- Lawn Mowers

- Ride-on & Zero Turn

- Chainsaws & Pole Saws For Sale

- Chipper Shredders

- Log Splitters

- Trimmers & Brushcutters

- Hedge Trimmers

- Blowers & VACs

- Edgers

- Battery and Electric Products

- Generators

- Concreting Equipment

- Pressure Washers

- Sprayers

- KombiSystem & MultiTools

- Garden Hand Tools

- Water Pumps

- Tillers and Cultivators

- Aerators

- Augers

- Engines

- Vacuum Cleaners & Sweepers

- Safety Gears

- Accessories

- Spare Parts

- Hire Department

- Second Hand Products

- Warehouse Clearance

- Gift Cards

- Summer Sale

Shop Now. Enjoy Now. Pay Later.

Available on full-priced items only (Sale items excluded)

Accessories

Spare Parts

Brands

Hot Dealsnew

- Second Hand

- Hire Department

Services

Stores

Gift Cards

Wishlist

My account

- Home Hydraulic or Kinetic Log Splitters: Which Is Better for Your Needs?

Hydraulic or Kinetic Log Splitters: Which Is Better for Your Needs?

If you’ve ever spent a day splitting wood with an axe, you’ll know just how physically draining and inefficient the process can be. Whether you’re stocking up for winter, clearing property, or collecting timber for commercial purposes, a reliable log splitter is well worth the investment.

However, not all log splitters are built the same, and there are two technologies that dominate the market; hydraulic and kinetic. Both have their own strengths and limitations, and finding the best option hinges on your own personal preferences and requirements.

Throughout this guide, we’ll break down the technical differences between hydraulic and kinetic log splitters, provide a clear analysis of what to consider before buying, and take a look at a few of the best models on the market today.

The Difference Between Hydraulic and Kinetic Technology

Hydraulic and kinetic splitters differ in how they generate and apply the force needed to break logs apart.

Hydraulic log splitters use fluid pressure to drive a piston that pushes a log into a fixed or moving wedge. This is a gradual build-up of force. The pressure is generated via a hydraulic pump powered by either a petrol engine or an electric motor.

The overall cycle (ram extension, splitting, and return) takes around 12 to 20 seconds depending on the model. What you get is an immense, consistent force that powers through hardwood, knots, and oversized logs.

Kinetic log splitters, on the other hand, operate by storing energy in a flywheel system. As the flywheel spins, it builds momentum. When triggered, a clutch engages and rapidly releases this stored energy, propelling the log into the wedge with great speed. The result is an incredibly fast cycle time, usually under three seconds. Kinetic models are generally lighter and require less maintenance; however, they offer lower splitting force and are best suited to softer wood or pre-cut rounds of moderate size.

In essence: hydraulic splitters are great for brute force, while kinetic splitters offer excellent speed.

Hydraulic Log Splitters: The Basics

Hydraulic log splitters are by far the most common type used in both residential and commercial settings. Their defining characteristic is the use of hydraulic pressure to drive the splitting mechanism. The system typically consists of:

- A petrol or electric engine

- A hydraulic pump

- A fluid reservoir

- Hydraulic cylinder

- Control valve

- Splitting wedge

The piston, which is driven by hydraulic fluid, applies immense pressure (often between 20 to 40 tonnes) to force a log through a wedge. These machines can be either horizontal, vertical, or convertible. The vertical position is especially useful when handling oversized or heavy logs, as it avoids the need to lift them onto the beam.

Advantages of hydraulic log splitters include:

- High splitting force: They are capable of tackling dense hardwoods like ironbark, red gum, and stringybark without stalling.

- Flexibility: The option to operate vertically or horizontally is highly beneficial in different working conditions.

- Consistency: Once running, the pressure applied is steady and effective, even on twisted or knotty grain.

The BWM LSD30 Deluxe Series Hydraulic Log Splitter with Lifter – On Sale Now!

Kinetic Log Splitters: An Overview

Kinetic log splitters have risen in popularity for their simplicity and speed. The core mechanism involves one or more spinning flywheels powered by a motor. Once the flywheels reach operating speed, a lever engages the rack and pinion system; releasing the stored kinetic energy into a fast-acting ram that slams the log into the wedge.

While most kinetic splitters offer lower tonnage (typically under 10 tonnes), the actual effectiveness can be misleading. Because of the speed of impact, even stubborn pieces often split quickly.

Benefits of kinetic splitters include:

- Speed: Cycle times are typically under 3 seconds. You can split multiple logs in the time it takes a hydraulic splitter to finish one.

- Simplicity: There’s no hydraulic fluid, pump, or valve to maintain. The internal system is mechanical and typically easier to troubleshoot.

- Weight and size: Most kinetic units are compact and easier to transport or move around the property.

The Masport 8 Ton Kinetic Log Splitter – Available Now at BW Machinery

A Look Into Our Current Log Splitters for Sale

BWM LSE30LC Essential Series Log Splitter (30 Tonnes, Loncin 6.5HP Engine)

This model combines a rugged steel frame with a reliable Loncin petrol engine and a high-performance hydraulic pump capable of delivering 30 tonnes of force. It can operate both horizontally and vertically, which is ideal for varied log sizes and weights.

With a 2-stage 11GPM / 3000psi hydraulic pump, a heavy-duty tow bar, and auto-return control valve, this unit suits both residential and small commercial workloads. The Loncin engine offers strong fuel efficiency and has gained a solid reputation for reliability at a mid-range price.

Key Features:

- Dual-position operation

- 30-tonne force suitable for hardwoods

- Towable with 50mm coupling

- Split logs up to 508mm long

- 2-year warranty on machine (3-year on engine)

Black Diamond 40 Ton Hydraulic Log Splitter (13HP Engine)

For anyone needing serious power, the Black Diamond LS40BD delivers 40 tonnes of splitting force powered by a 13HP petrol engine. Designed for demanding commercial or farm use, it includes a twin-stage 11GPM hydraulic pump and an industrial-grade build.

It offers a vertical and horizontal operation mode; a cast-steel wedge for long-term durability; and a substantial splitting capacity. This unit is ideal for processing a high volume of large hardwood logs.

Key Features:

- 40-tonne hydraulic force

- Heavy-duty wedge and frame

- Dual-mode splitting

- Jockey wheel and tow kit included

- Suited to logs over 600mm long

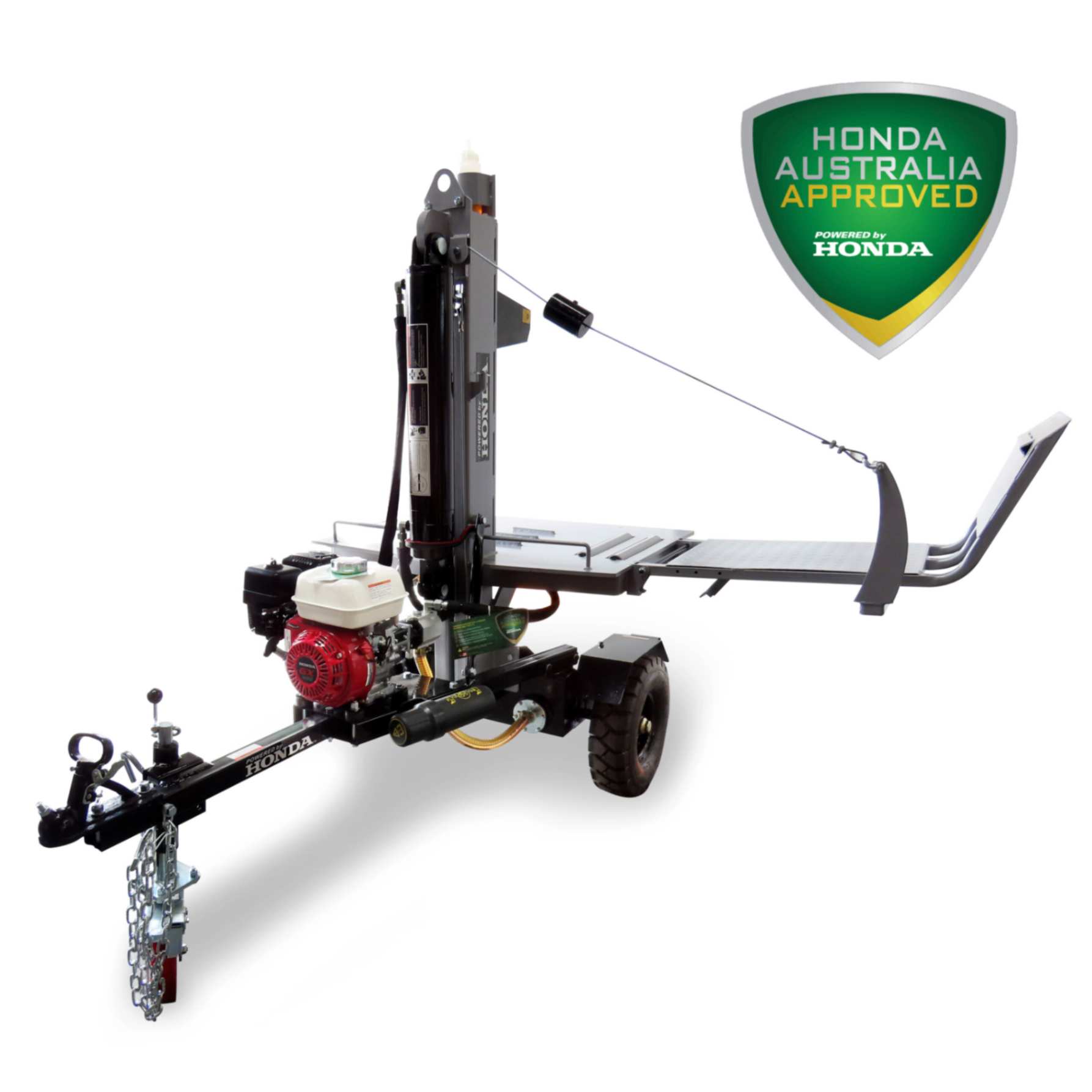

BWM LSV30H “Vertical” Log Splitter

The BWM LSV30H Log Splitter is powered by a genuine Honda GX200 OHV engine (Honda Australia Approved), and is built to perform in harsh Australian applications.

Featuring a 2-stage 12 GPM pump for maximum speed without loss of pressure, this machine is well equipped to split logs up to 30” in diameter with ease.

All our BWM log splitters have a 2 years warranty. For your peace of mind, we also offer money back guarantee if your log splitter fails to split your wood*.

Features:

- Powered by commercial Honda GX200 OHV Engine (Honda Australia Approved)

- 30 tons splitting force

- Split logs up to 30″ (762mm) in diameter

- 2 stage pump at 12GPM

- Up to 15 seconds cycle time

5 Things to Consider Before Choosing a Log Splitter

When deciding which log splitter to buy, ask yourself the following:

1. What kind of wood are you splitting?

Hardwoods like ironbark and box gum usually require a high-force hydraulic model. Softer species like pine or poplar, on the other hand, can be comfortably handled by a kinetic unit.

2. What size are your logs?

If you’re working with full rounds or anything wider than 400mm, a high-tonnage hydraulic splitter will be necessary. If your timber is already cut to size, a smaller unit will suffice.

3. How often will you use it?

Frequent users processing large volumes will always benefit from a machine that delivers on the key aspects of longevity and strength. More occasional users might prefer the convenience of a kinetic splitter.

4. Where will you be using it?

If you’re working on sloped, rugged, or remote land, portability becomes essential. Some hydraulic models come with tow bars, while kinetic models are often easier to push by hand.

5. How much maintenance are you prepared to do?

Hydraulic systems typically require a little more ongoing maintenance (such as oil changes, seal inspections, filter replacements). On the other side of the coin, kinetic machines require less attention, but can be more difficult to repair when issues arise with flywheels or clutches.

Explore Our Full Range of Log Splitters

Ready to pick up brand-new wood splitting equipment? We’ve got a fantastic range of log splitters for sale, both in store and online. From our very own BWM Products range to Masport, Oregon, and Black Diamond, we’ve got options to suit any situation.

Place an order right here online or pop down to one of our stores in Melbourne to view them up close. You can also pick up chainsaws, hedge trimmers, lawn mowers, accessories, and more!

-

Aug 14th, 20245 Compelling Reasons to Opt for a Masport Lawn Mower

Aug 14th, 20245 Compelling Reasons to Opt for a Masport Lawn MowerOn the hunt for a new lawn mower? Wondering if these are any good? As …

Read More -

Oct 01st, 2024How Often Should You Service a Ride-On Mower? A Maintenance Guide

Oct 01st, 2024How Often Should You Service a Ride-On Mower? A Maintenance GuideFrom household maintenance to commercial gardening, ride-on mowers can really make landscaping a breeze. However, …

Read More -

Nov 01st, 2024Why a Victa Lawn Mower is the Best Choice: 5 Key Reasons

Nov 01st, 2024Why a Victa Lawn Mower is the Best Choice: 5 Key ReasonsOperating for more than 70 years, Victa is a name that’s synonymous with high-quality outdoor …

Read More -

Dec 02nd, 2024How Do You Clean a Wood Chipper? Tips for Proper Maintenance

Dec 02nd, 2024How Do You Clean a Wood Chipper? Tips for Proper MaintenanceIf you’ve got a wood chipper, keeping it clean is undoubtedly the best way to …

Read More -

Jan 16th, 2025What to Look for When Buying a Log Splitter: Key Features to Consider

Jan 16th, 2025What to Look for When Buying a Log Splitter: Key Features to ConsiderIf manually splitting wood feels like a chore, a log splitter can make a world …

Read More -

Feb 05th, 2025What Features Should You Consider When Buying A Hedge Trimmer?

Feb 05th, 2025What Features Should You Consider When Buying A Hedge Trimmer?In the market for a brand-new hedge trimmer? Whether you’re planning to use it occasionally …

Read More -

Mar 21st, 20257 Reasons to Invest in a Honda Lawn Mower

Mar 21st, 20257 Reasons to Invest in a Honda Lawn MowerHonda has been a staple of the automotive industry for almost 80 years, consistently building …

Read More -

Apr 14th, 2025Stihl or Husqvarna Concrete Saws: Which is Best for You?

Apr 14th, 2025Stihl or Husqvarna Concrete Saws: Which is Best for You?In the market for brand-new concrete saws? Whether you’re cutting concrete on a major construction …

Read More -

May 30th, 2025Advantages of Battery Lawn Mowers: Is It the Right Choice for You?

May 30th, 2025Advantages of Battery Lawn Mowers: Is It the Right Choice for You?In the market for a brand-new lawn mower? Looking for an alternative to traditional petrol …

Read More

Due to supplier regulations. the {{PRODUCT_NAME}} can only be delivered to address within the Melbourne Metropolitan Region.

if you`re inside this area. please click ok to checkout with your order. Otherwise, please click cancel or call us on 1300 454 585 to discuss comparable products..