-

Shop By CategoryProducts

- Specials

- Lawn Mowers

- Ride-on & Zero Turn

- Chainsaws & Pole Saws For Sale

- Chipper Shredders

- Log Splitters

- Trimmers & Brushcutters

- Hedge Trimmers

- Blowers & VACs

- Edgers

- Battery and Electric Products

- Generators

- Concreting Equipment

- Pressure Washers

- Sprayers

- KombiSystem & MultiTools

- Garden Hand Tools

- Water Pumps

- Tillers and Cultivators

- Aerators

- Augers

- Engines

- Vacuum Cleaners & Sweepers

- Safety Gears

- Accessories

- Spare Parts

- Hire Department

- Second Hand Products

- Warehouse Clearance

- Gift Cards

- Summer Sale

Shop Now. Enjoy Now. Pay Later.

Available on full-priced items only (Sale items excluded)

Accessories

Spare Parts

Brands

Hot Dealsnew

- Second Hand

- Hire Department

Services

Stores

Gift Cards

Wishlist

My account

- Home How To Maintain Your Hedge Trimmers for Long-Lasting Performance

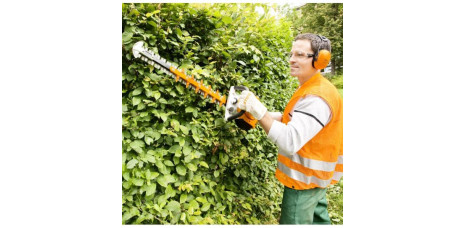

How To Maintain Your Hedge Trimmers for Long-Lasting Performance

Owning a high-quality hedge trimmer makes gardening much easier, but these tools require consistent care to remain effective. Whether you use a petrol hedge trimmer for professional landscaping or a battery hedge trimmer for residential tasks, the cutting performance depends entirely on the condition of the blades and the motor. Without regular maintenance, even the best gear will eventually struggle to cut through thick branches, leading to jagged edges and potential plant disease.

At B.W. Machinery, we understand that your garden tools are an investment. Proper upkeep prevents costly repairs and extends the lifespan of your equipment. This guide covers everything you need to know about keeping your trimmers in top shape, from sharpening a hedge trimmer to cleaning the blades and battery contacts.

Why It’s Important to Clean Your Hedge Trimmer

Cleaning is the most basic yet most overlooked part of tool ownership. Every time you trim, the cutting attachment comes into contact with sap, moisture, and debris. This sap, often called resin, acts like glue as it dries. It binds the blade teeth together, which forces the motor to work harder to move the blades.

If you ignore the buildup of resin, the friction between the blades increases. This generates excess heat and can cause permanent damage to the gear case. For those using cordless models, this extra friction drains the lithium-ion battery much faster, reducing your work time. Regular cleaning keeps the blades sliding smoothly and prevents the corrosion protection coating from wearing off.

Do I Need to Lubricate My Hedge Trimmer?

Yes, lubrication is essential! A hedge trimmer consists of two blades that slide rapidly against one another. Without a layer of oil, the metal-on-metal contact causes wear and tear. Lubrication serves several purposes: it reduces friction, prevents the blades from sticking, and provides a barrier against moisture that causes rust.

If you notice your hedge trimmer is starting to feel sluggish or the blades are getting hot to the touch, it is likely lacking lubrication. You should apply lubricant before you start working and again after you finish cleaning the tool.

For general use, a high-quality multipurpose oil or a specialised spray-on lubricant works well. Avoid using heavy greases on the blades themselves, as these can attract more dust and grit, creating an abrasive paste that dulls the sharp blades faster. For the internal gear case, you should consult your user manual for the specific type of grease required, as this part of the tool handles significant mechanical stress.

How Often Should I Clean and Sharpen My Hedge Trimmer Blades?

The frequency of maintenance depends on how often you use the tool. As a general rule, you should perform a quick clean after every use. A deeper cleaning with resin solvent should happen whenever you notice sap buildup.

Sharpening should be done whenever you feel the cutting performance start to drop. If the blades are tearing the leaves rather than slicing them cleanly, it is time to sharpen. For most residential users, sharpening once or twice a year is sufficient. However, if you are using your hedge trimmer frequently for professional work, you might need to touch up the edges every 20 to 30 hours of use.

How to Sharpen a Hedge Trimmer

Sharpening a hedge trimmer requires patience and the right tools. You will need a flat file or a small whetstone.

- Clean the blades first: Use a resin remover to get rid of all sap so you can see the metal clearly.

- Align the teeth: Move the blades until the cutting teeth are aligned.

- File in one direction: Use a flat file to sharpen the cutting edge of each tooth. Always file in the direction of the cutting edge, moving away from the body of the tool.

- Maintain the angle: Try to match the original factory angle of the tooth. Usually, this is around 45 degrees.

- Remove burrs: After filing the top side, you may find small metal burrs on the underside. Lightly run the file along the bottom of the blade to smooth these out.

- Lubricate: Once sharpened, apply oil to protect the fresh metal from rust.

If the blades are badly nicked from hitting wire fences or stones, you may need to visit a professional for a machine grind. Expert advice is always available at B.W. Machinery if you are unsure about the state of your blades. Blade sharpening is also offered in our workshops at each of our stores across Melbourne.

What Safety Precautions Should Be Taken When Maintaining Hedge Trimmers?

Safety is the first priority when handling any power tool with sharp edges. Before you begin any maintenance tasks, you must disable the power source.

- For a petrol hedge trimmer, remove the spark plugs to prevent accidental starting.

- For battery powered hedge trimmers, remove the battery pack completely.

- For electric models, unplug the extension cable from the mains.

Always wear thick work gloves to protect your hands from the blade teeth. Wear safety glasses when sharpening or using spray cleaners to keep metal filings and chemicals out of your eyes. Ensure your workspace is well-lit and stable. If you are working on long reach hedge trimmers, be mindful of the extra length and weight when positioning the tool on a workbench.

Hedge Trimmer Not Cutting: What is the Cause?

If your trimmer is running but not cutting effectively, the most common culprit is dull blades. However, several other factors could be at play:

- Sap Buildup: If the blades are stuck together with resin, they won’t move fast enough to cut.

- Loose Blade Bolts: If the bolts holding the cutting blade together are loose, the blades will separate slightly, allowing branches to slide between them rather than being cut.

- Damaged Teeth: A single bent tooth can throw off the entire alignment.

- Engine or Battery Issues: On a battery hedge trimmer setup, a low charge or failing lithium-ion battery might not provide enough power to maintain the necessary blade speed. On petrol models, a clogged air filter or old spark plugs can cause the engine to bog down under load.

Routine Inspection and Cleaning

Routine checks prevent small issues from becoming expensive failures. Every month, inspect the following:

- Air Intakes: Ensure the cooling vents are clear of leaves and dust.

- Handle Grips: Check that the handles are secure and the vibration dampening system is intact.

- Fasteners: Vibrations can loosen screws and bolts over time, so tighten any that feel loose.

- Fuel System: For petrol units, check the spark plugs, fuel tank for debris and inspect the fuel lines for cracks.

If you use Husqvarna hedge trimmers, pay close attention to the air filter. A dirty filter restricts airflow, leading to poor combustion and increased fuel consumption.

Hedge Trimmer Maintenance Tools and Products from B.W Machinery

Safety Gear

When working with or maintaining your hedge trimmer, safety should always be your number one priority. B.W. Machinery stocks earmuffs and earplugs to protect your hearing from loud noise, which can cause hearing loss over time. We also stock eye protection, including helmets, face shields and impact-resistant safety glasses with UV coating, which will keep your eyes safe from flying sticks and the sun. Finally, when using cleaning chemicals and sharp blades, it is important to wear gloves that are both cut-resistant and can withstand potentially harmful chemical compounds.

Lubricants and Cleaners

As discussed, a clean and well-lubricated hedge trimmer is safer, more efficient and will last longer without needing repairs. That is why we stock a variety of products designed to clean, lubricate and protect your hedge trimmer blades. For STIHL hedge trimmers, we highly recommend the STIHL SuperClean Resin Solvent, which works to clean resin from sap, lubricate the blades and protect against rust, all in one convenient product! Simply spray the blades after each use and enjoy sharper, cleaner and more effective hedge trimmers for years to come.

By following these maintenance steps, you ensure that your equipment remains a reliable part of your gardening kit. For more information on the best brands or to pick up the supplies you need for your next round of maintenance, contact the team at B.W. Machinery on 1300 454 585. We provide the gear and the knowledge to help you keep your hedges looking their best across Australia.

-

Aug 14th, 20245 Compelling Reasons to Opt for a Masport Lawn Mower

Aug 14th, 20245 Compelling Reasons to Opt for a Masport Lawn MowerOn the hunt for a new lawn mower? Wondering if these are any good? As …

Read More -

Oct 01st, 2024How Often Should You Service a Ride-On Mower? A Maintenance Guide

Oct 01st, 2024How Often Should You Service a Ride-On Mower? A Maintenance GuideFrom household maintenance to commercial gardening, ride-on mowers can really make landscaping a breeze. However, …

Read More -

Nov 01st, 2024Why a Victa Lawn Mower is the Best Choice: 5 Key Reasons

Nov 01st, 2024Why a Victa Lawn Mower is the Best Choice: 5 Key ReasonsOperating for more than 70 years, Victa is a name that’s synonymous with high-quality outdoor …

Read More -

Dec 02nd, 2024How Do You Clean a Wood Chipper? Tips for Proper Maintenance

Dec 02nd, 2024How Do You Clean a Wood Chipper? Tips for Proper MaintenanceIf you’ve got a wood chipper, keeping it clean is undoubtedly the best way to …

Read More -

Jan 16th, 2025What to Look for When Buying a Log Splitter: Key Features to Consider

Jan 16th, 2025What to Look for When Buying a Log Splitter: Key Features to ConsiderIf manually splitting wood feels like a chore, a log splitter can make a world …

Read More -

Feb 05th, 2025What Features Should You Consider When Buying A Hedge Trimmer?

Feb 05th, 2025What Features Should You Consider When Buying A Hedge Trimmer?In the market for a brand-new hedge trimmer? Whether you’re planning to use it occasionally …

Read More -

Mar 21st, 20257 Reasons to Invest in a Honda Lawn Mower

Mar 21st, 20257 Reasons to Invest in a Honda Lawn MowerHonda has been a staple of the automotive industry for almost 80 years, consistently building …

Read More -

Apr 14th, 2025Stihl or Husqvarna Concrete Saws: Which is Best for You?

Apr 14th, 2025Stihl or Husqvarna Concrete Saws: Which is Best for You?In the market for brand-new concrete saws? Whether you’re cutting concrete on a major construction …

Read More -

May 30th, 2025Advantages of Battery Lawn Mowers: Is It the Right Choice for You?

May 30th, 2025Advantages of Battery Lawn Mowers: Is It the Right Choice for You?In the market for a brand-new lawn mower? Looking for an alternative to traditional petrol …

Read More -

Jun 30th, 2025Hydraulic or Kinetic Log Splitters: Which Is Better for Your Needs?

Jun 30th, 2025Hydraulic or Kinetic Log Splitters: Which Is Better for Your Needs?If you’ve ever spent a day splitting wood with an axe, you’ll know just how …

Read More

Due to supplier regulations. the {{PRODUCT_NAME}} can only be delivered to address within the Melbourne Metropolitan Region.

if you`re inside this area. please click ok to checkout with your order. Otherwise, please click cancel or call us on 1300 454 585 to discuss comparable products..